The Rise of Automation

In today's technologically advanced world, automation has played a key role in improving efficiency and productivity across various industries. From advanced manufacturing plants to complex machinery, automation employs the use of control systems that rely on sensing, feedback and actuation to perform complex tasks with high precision and speed. At the heart of any electro-mechanical control system lies a critical component - the electro hydraulic servo valve.

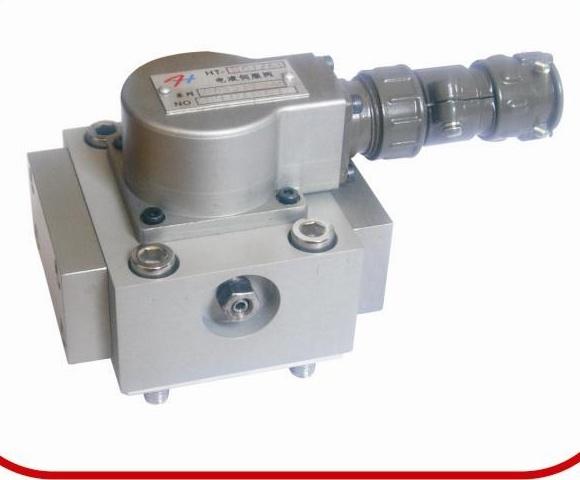

What is an Electro Hydraulic Servo Valve?

An electro hydraulic servo valve is a valve that controls the flow of hydraulic fluid in a hydraulic system. It utilizes electric control signals to proportionately regulate the flow of hydraulic fluid in order to manipulate hydraulic actuators like hydraulic cylinders and motors. These servo valves provide precise control over hydraulic pressure and flow for various industrial applications that demand positional accuracy and speed.

The innovative design of modern electro hydraulic servo valves integrates mechatronic principles. A typical servo valve consists of a solenoid actuator, a valve spool, a feedback sensor and sophisticated electronic controls. When an electric current is passed through the solenoid, it generates a magnetic field that pushes or pulls the valve spool. This motion of the spool regulates the flow of pressurized hydraulic fluid from the valve's inlet port to its outlet ports. Advanced feedback sensing and electronic controls enable high-speed, highly stable and repeatable hydraulic actuation.

Working of an Electro Hydraulic Servo Valve

To understand the working of an electro hydraulic servo valve, let us look at its core components and functions:

- Solenoid Actuator: This uses an electric signal to generate a proportional magnetic field for controlling the position of the valve spool.

- Valve Spool: The spool regulates the flow of hydraulic fluid from the valve's inlet port to one of its outlet ports based on its own position within the solenoid assembly.

- Feedback Sensor: Precisely monitors the position of the spool and provides feedback for closed-loop control of hydraulic actuation.

- Electronic Control Unit: Processes the electric control signal and feedback to precisely regulate solenoid current for precise spool positioning and hydraulic flow control.

When an electric signal is sent to the solenoid, it pulls/pushes the spool to a certain position. Based on spool position, hydraulic fluid is routed from the inlet port to one of the outlet ports, pressurizing the corresponding hydraulic actuator chamber. The feedback sensor continuously monitors spool motion and provides positional data to the controller for closed-loop corrections. This enables precise hydraulic actuation as demanded by the application.

Applications of Electro Hydraulic Servo Valves

Given their high performance capabilities, electro hydraulic servo valves find widespread application across different industries:

Flight Control Systems

Servo valves provide fail-safe hydraulic actuation for critical flight control surfaces like ailerons, elevators and rudders. Their high bandwidth and repeatability are crucial for safe aircraft maneuvering.

Robotics

Robotic arms, wrists, grippers and other joints require fast and precise motion control enabled by electro hydraulic actuation systems incorporating servo valves.

Material Testing Machines

Servo valves drive hydraulic actuators that carry out fatigue, tensile and other material tests requiring repetitively programmable loading profiles.

Plastic Injection Molding Machines

Servo valves regulate clamp force and speed in injection molding machines to ensure uniform part quality during high-speed production runs.

Off-Highway Equipment

Hydraulically powered excavators, loaders, snow plows etc. employ servo valves for smooth and responsive motion of booms, buckets and other attachments.

Advantages of Electro Hydraulic Servo Valve Technology

Compared to alternative actuation methods, electro hydraulic servo valve technology offers numerous advantages:

- High Force and Power Density: Hydraulic actuation enables generation of large mechanical forces with compact package size.

- Fast Response: Servo valves provide rapid positioning of hydraulic actuators within microseconds for agile motion control.

- Precise Control: Feedback-controlled valve design results in repeatable positioning accuracy of < 0.1% of full scale.

- Rugged Reliability: Hydraulic drives stand up well to shock, vibration and demanding environmental conditions.

- Fail-Safe Design: Servo valves naturally fail to a neutral state preventing uncontrolled actuator motion.

- Cost Effectiveness: Hydraulics offer a relatively low-cost solution for applications needing high power-to-weight ratio.

- Wide Bandwidth: Sophisticated electronics enable servo valves to provide servo-grade velocity and acceleration control.

Future Outlook

As automation trends accelerate in various industries, demand for advanced mechatronic control technologies like electro hydraulic servo valves will continue rising. Moreover, ongoing innovations will further enhance valve performance characteristics of bandwidth, precision, miniaturization and energy-efficiency to enable more compact and intelligent systems of the future. Servo valves will remain essential for applications where responsive, high-force motion control is paramount. The future appears bright for continued advancement of electro hydraulic servo valve technology.

Get more insights on this topic: https://www.newsanalyticspro.com/electro-hydraulic-servo-valve-market-industry-insightstrendselectro-hydraulic-servo-valve-market/

Explore more information on this topic, Please visit: https://coolbio.org/understanding-human-embryonic-stem-cells/