Radio frequency identification (RFID) is a technology that utilizes radio waves to automatically identify objects. RFID tags are affixed to or embedded in products, assets, and packages to enable radio frequency communication of identity and other information wirelessly. Over the past decade, RFID adoption has increased significantly across various industries as organizations recognize its potential to streamline operations, boost supply chain visibility, and enhance customer experience.

What is RFID?

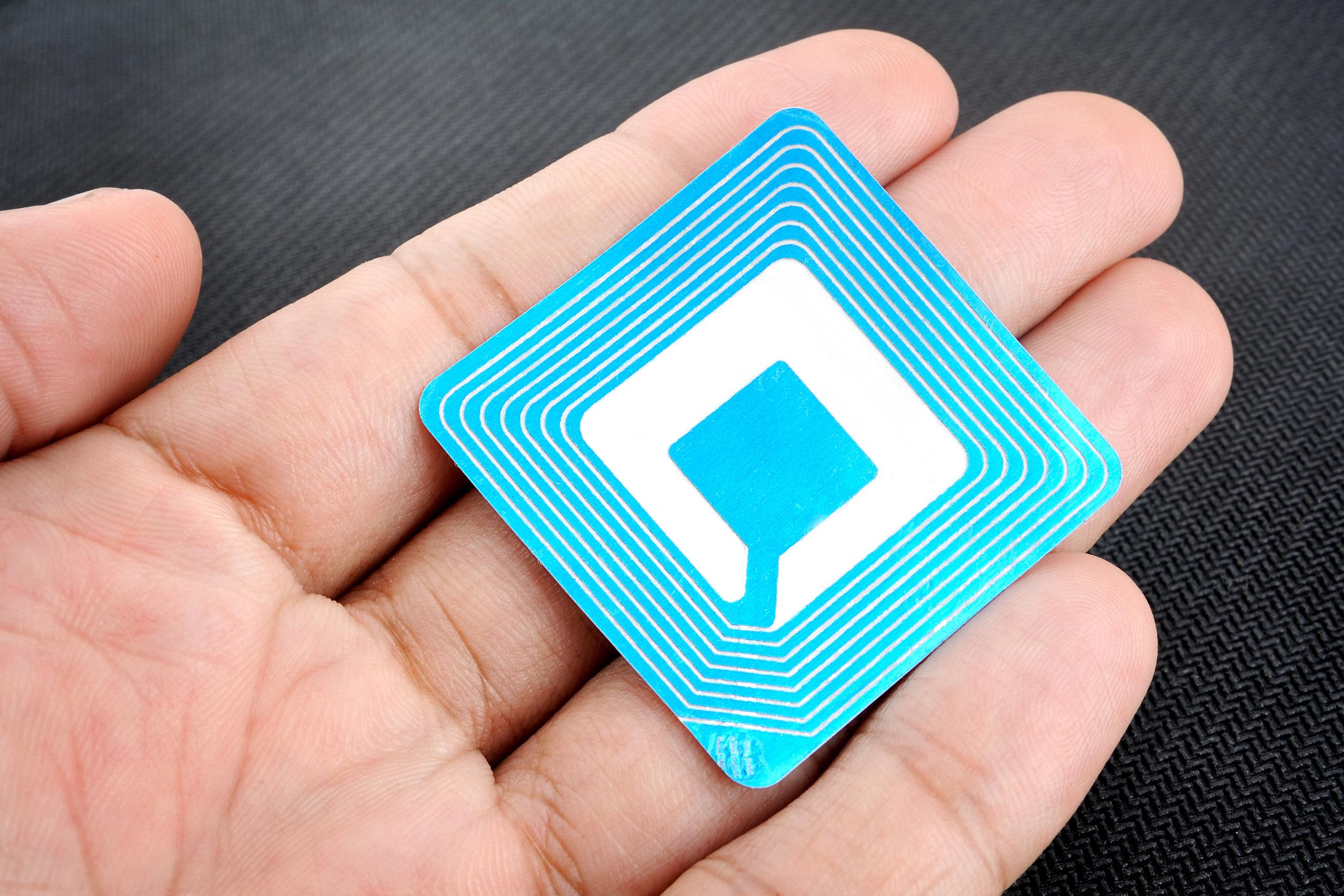

At the core, an RFID system consists of three components - an antenna or coil, a transceiver (with decoder), and a transponder (RFID tag) electronically programmed with unique information. The antenna emits radio waves to power a tag and read and write data to it. Tags can either be passive, active or battery-assisted passive. Passive tags have no internal power source and require an external energy source to operate. Active tags have an on-board battery to power the tag, while battery-assisted tags use a small battery to run the chip's circuitry and the antenna is powered by energy received from the reader.

RFID Tags come in various forms like key fobs, contactless payment cards, security badges and shipping container labels. Different frequency bands - low, high and ultra-high - are used depending on the intended application and range requirements. Unlike barcodes that need to be within the line of sight, RFID tags can be read through other objects and have longer read ranges as well as higher data capacity.

Boosting Supply Chain Visibility

RFID is transforming supply chain visibility and management. Major companies in different industries have deployed RFID to better track shipments, assets and inventory throughout their extended supply chains. For example, fashion and apparel retailers track individual garments right from the factory to ensure correct sizing and colors reach stores. Manufacturers gain real-time insight into the location and status of shipments, work-in-progress orders, tools and equipment across factories and distribution centers worldwide.

Perishable food suppliers leveraging RFID can get instant alerts if temperature and humidity breach set thresholds during transportation. RFID-empowered asset tracking solutions enable equipment-intensive industries like oil & gas, mining and construction to locate tools and machineries scattered across large project sites within seconds. The real-time visibility afforded by RFID eliminates waste from expired, lost or incorrectly shipped products and boosts supply chain efficiencies significantly.

Streamlining Warehouse and Distribution Operations

Warehouses and distribution centers are increasingly deploying RFID solutions to automate processes and optimize space utilization. RFID-enabled put-to-light systems guide fulfillment operators to the exact storage locations of picked inventory items. Voice-directed picking using RFID increases accuracy while reducing training times. RFID-driven automated sorting systems at high-volume parcel centers rapidly route shipments down subsequent workflow paths based on address data encoded in tags.

Dynamic slotting guided by RFID readings optimally arranges fast-moving and slow-moving SKUs for maximum throughput in warehouses. Cross-docking operations leverage RFID to swiftly distribute back-of-store deliveries directly to trucks headed to retail stores, bypassing storage altogether. RFID-driven automated guided vehicles (AGVs) and material handling equipment ensure faultless inventory movement within distribution centers operating on lean principles. As a result, order fulfillment cycles are slashed by 30-50% using RFID in warehouses.

Enhancing Customer Experience

At the retail front, RFID is augmenting store operations and elevating shopping experiences. RFID-powered smart fitting rooms notify staff of styled items tried on for expedited purchase assistance. Electronic article surveillance (EAS) systems leverage RFID to prevent theft and boost store security. Apparel retailers pair Bluetooth Low Energy (BLE) beacons with RFID tags to serve personalized promotions and product recommendations to shoppers based on their viewing history and location within stores.

Self-checkout kiosks supported by RFID accelerate transactions by identifying items placed in carts and bags without barcodes needing scans. Forward-thinking apparel stores let shoppers check inventory availability of viewed items from fitting rooms by simply tapping RFID tags. The convergence of IoT and RFID will birth many new use cases like automated replenishment of fitting room mirrors and smart mirrors updating virtual outfits in real-time as physical garments are tried on. Holistic adoption of RFID is elevating omnichannel experiences, modernizing store forms and driving greater customer loyalty.

Overcoming RFID Challenges

Despite evident benefits, RFID implementation remains a challenge for some due its initial capital costs and technical complexities. Interference from liquids and metals can attenuate radio signals, hampering tag reads even in distribution environments. Strict regulations surrounding frequencies utilized can constrain deployments. Data privacy concerns linger regarding location tracking through persistent identifiers encoded in tags. However, costs have decreased significantly with rapid scaling of volumes during the past decade.

Open consortiums and technology advancements are effectively addressing technical bottlenecks like multi-tag collisions and extending reading distances. Cloud-based RFID solutions with centralized data analytics capabilities are simplifying adoption. Vendor partnerships are helping smaller companies pilot and scale up RFID use cases phased over time to minimize disruptions. With digitization accelerating across supply chains, RFID’s strategic importance will rise steadily even as deployment obstructions continue diminishing.

The Future of RFID

Looking ahead, new-generation chipless RFID with no silicon chips and carbon nanotube-enabled ultra-low cost, flexible tags will expand tagging applications to consumer products, pharmaceuticals and more. Narrowband Internet of Things (NB-IoT) and 5G networks will support real-time tracking of high-value mobile assets globally. Blockchain ledgers combined with item-level tagging will authenticate luxury goods, pharmaceuticals and construction materials against counterfeiting.

RFID integration into AI and computer vision stacks will guide autonomous robots, guided vehicles and cobots through logistics facilities supporting Industry 4.0 principles. Ubiquitous printing of smart RFID skins and labels onto 3D printed parts will pave way for tracking individualized components in manufacturing. Persistent identifiers derived from RFID could emerge as alternative means for digital identity verification to streamline online transactions. With rapid digitization across industries and evolving integration opportunities, RFID's strategic relevance and scope are bound to grow exponentially in the years ahead.

Get more insights on Radio Frequency Identification