What are In-Mold Labels?

In-mold labels, also known as in-mold decorating, are labels that are applied inside plastic containers during the blow molding or injection molding process. The label material is coated onto the plastic material while it is still molten and gets integrated with the plastic. This eliminates the need for secondary labeling after molding.

Types of In-Mold Label Materials

There are different types of materials that can be used to produce in-mold labels:

- Polypropylene (PP): PP is the most commonly used material for In-Mold Labels due to its good chemical resistance and compatibility with PP container materials. It can withstand high molding temperatures.

- Polyethylene (PE): PE labels are compatible with PE containers and more price friendly compared to PP labels. However, their temperature resistance is lower than PP.

- Polyvinyl Chloride (PVC): PVC films are low cost but have limitations in withstanding higher molding temperatures. They are usually used for injection stretch blow molding.

- Non-PVC: These printable films based on olefin polymers are better alternatives to PVC due to their non-toxic nature. They have good clarity, temperature and chemical resistance.

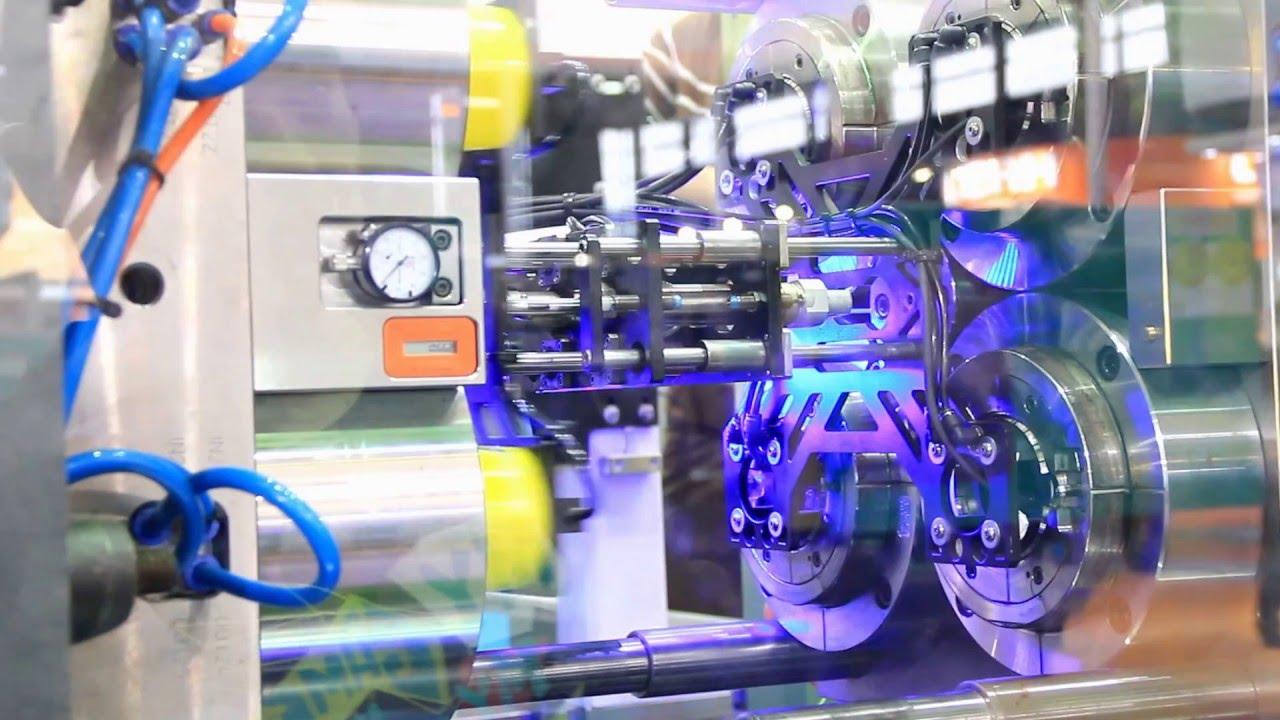

Processing Techniques for In-Mold Labels

There are two main processing techniques used for manufacturing in-mold labels:

- In-Mold Label Insert Molding: In this process, a preformed label made of label material is first placed inside an open mold cavity. Then, molten plastic is injected which encapsulates the label during molding.

- In-Mold Label Film Insert Molding: Here an unformed film of label material like PP is first placed inside the mold. During the molding process, the film melts and fuses with the molten plastic material as it takes the shape of the mold cavity.

Benefits of In-Mold Labeling

- Increased Aesthetics: IML provides a seamless integration of the label with clear container walls without any extra adhesive usage or overlapping. This results in a premium look.

- Durability: As the label material fuses with the container material, in-mold labels withstand various environmental conditions like moisture, chemicals, heat, etc. better than pressure sensitive labels.

- Tamper Evidence: Any attempt to remove an IML damages the container, clearly indicating tampering. This makes them suitable for food, beverage and pharmaceutical products requiring product safety.

- Lower Costs: IML eliminates the extra step of secondary labeling after molding. It reduces material wastage and gives cost benefits compared to pressure sensitive labels over long runs.

- Printing Flexibility: IML materials allow multi-color and hot stamping along with variable data printing technologies like inkjet for customized product labeling.

Applications of In-Mold Labels

Due to the above advantages, in-mold labels are used in a wide variety of rigid plastic containers and components across many industries:

- Food and Beverage: Common applications are aluminum & PET bottles, yogurt and margarine tubs, juice bottles, drink bottles, cans, etc. They are suitable for hot-fill containers with tamper evident seals.

- Household: IMLs label various household products like detergent bottles, kitchenware, storage containers, caps and closures, buckets, crates, etc.

- Healthcare: Pharmaceuticals, medical devices, diagnostic product containers use IMLs for their durability in supply chain and tamper evidence for product safety.

- Automotive: Fuel tanks, lubricant bottles, vehicle parts are among automotive applications that require robust labeling.

- Electronics: Components like computer casings, power banks, wiring harnesses utilize IML for aesthetic branding and product identification.

- Industrial: Bulk containers, lubricant pails, chemical drums employ IMLs that withstand harsh industrial environments and hazards.

Challenges in IML Production

While IMLs offermanyadvantages, their manufacturing involves certain difficulties:

- Mold Design: Complex molds are required that can insert and fuse the label film while also forming the container. This increases tooling costs.

- Material Wastage: As label films melt during molding, there is wastage up to 10-15% of material weight compared to PSL.

- Process Control: Maintaining consistent film insertion, thickness, orientation within tight tolerances needs careful process controls.

- Label Quality: Defects like bubbles, wrinkles or short shots can affect aesthetics and lead to rejects if process parameters are not optimized.

- Material Innovation: Developing new compatible label materials for new container substrates requires R&D investments.

With advancements in automation, simulation software and material sciences, manufacturers are constantly overcoming these limitations to advance in-mold labeling technology. When designed and produced properly, IMLs deliver compelling value for product identification and enhancement.

Get More Insights On In-Mold Labeling