CROMOPLASTICACMC uses a amazing mechanical scratching process to simply help create pore sites for the amazing chemistry to deposit a metallic layer. A procedure which was doratura galvanica created and proven out in 2011 when CROMOPLASTICACMC plated PBT connectors.

An electroless nickel or electroless copper is settled onto the plastic to create the initial layer to help make the portion conductive. This can be the final finish or instead, can be made a point of contact letting the improvement of electrolytic: silver, magic, nickel, cadmium, jar or zinc-nickel. Using a mechanical scratching pretreatment process can naturally make the appearance of the plating a dull or flat finish. CROMOPLASTICACMC could make this brilliant or glistening by making use of huge layer of electrolytic copper as much as 1000 micro inches thick. The reason being electrolytic copper has a self progressing property to simply help improve the top finish.

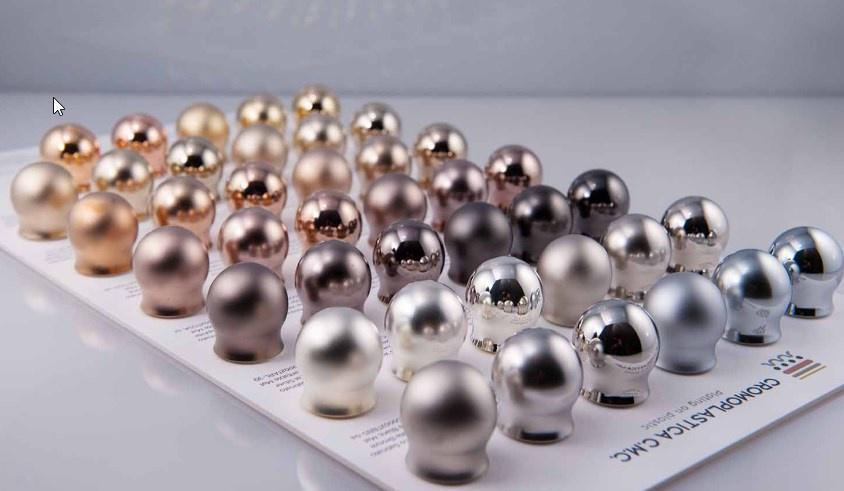

ELECTROPLATING 3D PRINTS

As 3D printers have developed, there's been more fascination with metalizing the merchandise they produce. Factors range why persons wish to metalize 3D produced materials, but the main two causes are for purpose or cosmetics. Before we discuss the plating, you need to find out what resources CROMOPLASTICACMC can metalize.

Acceptable Materials – Each product may respond differently to your plating process, but you want to look for a several critical points if you want to dish your part.