Introduction

In today's rapidly evolving industrial landscape, CNC manufacturing has emerged as a game-changer. CNC, which stands for Computer Numerical Control, revolutionizes the way products are designed and manufactured. This technology offers numerous advantages that have transformed the manufacturing industry, making it more efficient, precise, and cost-effective.

Enhanced Precision and Accuracy

One of the key advantages of CNC manufacturing is its ability to deliver unmatched precision and accuracy. Traditional manufacturing methods often rely on manual labor, which can introduce human errors and inconsistencies. However, CNC machines operate based on computer programs, ensuring precise and repeatable results with minimal deviation. This level of accuracy is particularly crucial in industries such as aerospace, automotive, and medical, where even the slightest deviation can have significant consequences.

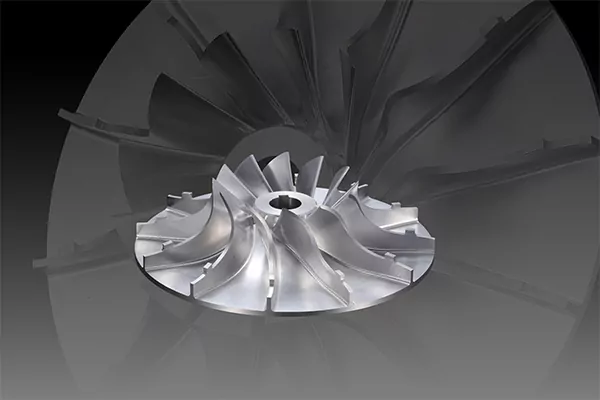

For example, in the aerospace industry, CNC manufacturing plays a vital role in producing complex components like turbine blades. These components require intricate designs and tight tolerances, which can be achieved consistently through CNC machining. The use of CNC technology eliminates the risk of human error and ensures that each component meets the required specifications.

Increased Efficiency and Productivity

CNC manufacturing significantly enhances efficiency and productivity in the industrial landscape. Unlike traditional manufacturing methods that rely heavily on manual labor, CNC machines operate autonomously, reducing the need for human intervention. This automation allows for continuous production, 24/7 operation, and faster turnaround times.

Furthermore, CNC machines can perform multiple tasks simultaneously, thanks to their multitasking capabilities. This means that complex operations, such as milling, drilling, and turning, can be carried out in a single setup, eliminating the need for multiple machines and reducing production time. As a result, manufacturers can meet tight deadlines and fulfill customer demands more efficiently.

Cost Savings and Waste Reduction

CNC manufacturing offers significant cost savings and waste reduction opportunities. By automating the production process, manufacturers can minimize labor costs associated with manual operations. Additionally, CNC machines are highly efficient in material utilization, reducing waste and optimizing raw material usage.

Moreover, CNC technology enables the production of intricate designs that would be challenging or impossible to achieve using traditional methods. This eliminates the need for costly secondary operations and reduces the overall production costs. Manufacturers can also save on tooling costs as CNC machines can use a single tool to perform multiple operations, reducing the need for specialized tools.

Flexibility and Adaptability

CNC manufacturing offers unparalleled flexibility and adaptability in the modern industrial landscape. With CNC machines, manufacturers can easily reprogram the machines to produce different parts or modify existing designs. This flexibility allows for quick adaptation to changing market demands and enables manufacturers to stay competitive in dynamic industries.

Furthermore, CNC machines can work with a wide range of materials, including metals, plastics, and composites. This versatility opens up new possibilities for product design and innovation. Manufacturers can experiment with different materials and create complex geometries that were previously unattainable, expanding their product offerings and attracting a broader customer base.

Conclusion

The advantages of cnc manufacturing in the modern industrial landscape are undeniable. From enhanced precision and accuracy to increased efficiency and productivity, CNC technology has revolutionized the way products are manufactured. The cost savings, waste reduction, and flexibility offered by CNC machines further contribute to its appeal. As industries continue to evolve, CNC manufacturing will undoubtedly play a pivotal role in shaping the future of manufacturing.