Portable laser engravers are important in many industries for marking many materials because of their ease of operation and industrial compatibility. There are many types and variations of portable laser engravers.

Portable laser engraving machines are machines used in many manufacturing industries to mark plastics and metals. It is a user-friendly machine for different marking projects. However, some people do not know what it does and how it operates.

To solve this problem, we made a guide to using a portable laser engraver. This guide will thoroughly discuss the laser engraving process, the characteristics of a portable laser engraver, and how to choose the right one.

What is laser engraving?

Laser engraving is a subtractive manufacturing process that involves creating an image on a material using a laser beam from a laser engraver. Therefore, laser engraving is common in the automotive, aerospace and electronics industries.

Difference Between Laser Marking, Etching and Engraving

Laser engraving is a common manufacturing process with a wide range of applications. However, because of the "laser" labeling, most people confuse it with other laser processes like laser etching and laser marking.

laser etching

Laser etching is a subset of laser engraving that uses heat from a laser beam from a laser etcher to melt material. The material expands, forming a raised cavity. Therefore, it modifies and enhances physical properties, such as the reflectivity of the material. Laser etching is a popular process for metals.

Laser Marking

Laser marking involves making high-contrast markings on materials using a lower portable laser marking machine. Unlike laser etching and laser engraving, it does not alter the condition of the material. It will only cause discoloration of the material through oxidation of the mark itself.

Laser etching, marking and engraving can use a laser beam to create images on different materials. However, the difference between the three is in the making of the markers. Laser engraving removes some material. Laser etching changes the top layer of the material. Laser marking creates an image on a material without removing or changing the material.

What is a Portable Laser Engraver?

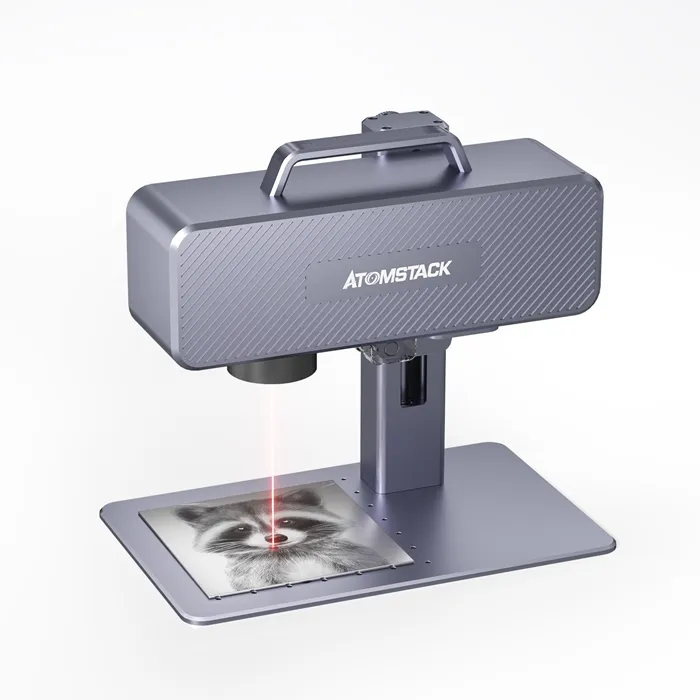

Portable laser engravers or handheld laser engravers are popular tools in the automotive, aerospace, electronics industries because of their portability and ease of operation. Unlike traditional engraving machines, portable engraving machines consist of two general parts: the hand-held part and the box. These two components are responsible for machine engraving functions and other complementary functions.

How does a portable laser engraver work?

Choosing the right portable laser engraver requires understanding how the machine works and other required prerequisites. These can be demanding. However, here are some factors that will help you choose the best portable laser engraver.

How to choose the right portable laser engraving machine?

· Price

Price is an important factor when deciding to buy a portable laser engraver. Unlike traditional laser engravers, portable engravers are both portable and ideal for industrial use. Portable engraving machines also have greater operational convenience due to their features. Therefore, the price to get one is higher than a traditional laser engraver.

· Software compatibility

Software compatibility is an important factor when looking for a atomstack p9 m50 portable laser engraver. There are two options. You can get a portable laser engraver with its software. Therefore, you must ensure that your design is suitable for the engraving machine's software. The second option is to buy a portable laser engraver that can be used with your software. So when you use your software to create a design, it will be compatible with it. A good example of a software compatible engraver you can get is a portable 20w fiber laser marker.

· Energy source

What do you think is the reason for the popularity of portable laser engravers in terms of power supply, which will improve the convenience of operation? Battery backed, of course! Combined with wired power, portable laser engravers with battery options can also be easily used in any condition.

· Laser source

The laser source is also an important feature when purchasing a portable laser engraver. Look for a machine that uses a noise-free laser source, making the process environmentally friendly.

· Connection options

While this may not be necessary, it is never less important. It's best to find a portable laser engraver that doesn't require a direct connection to your computer. Most portable laser engravers we know use a USB stick to connect to a computer. This further ensures ease of operation.

· weight

Portable laser engravers also vary in portability due to weight factors. This is based on the different characteristics of the machine and optimizations given by the manufacturer. Therefore, when choosing a portable laser engraving machine, choose a laser engraving machine of the right size and weight with complementary functions. However, be aware that weight also drives price. Therefore, smaller-sized portable laser engraving machines that can be used in industry, such as portable fiber laser marking machines, have more functions and higher prices.