When it comes to optimizing operations in the James Andrews industry, implementing effective turning service strategies is crucial for achieving efficiency and productivity. By focusing on streamlining operations through innovative turning service approaches, companies can enhance their overall performance and gain a competitive edge in the market.

The Importance of Turning Services

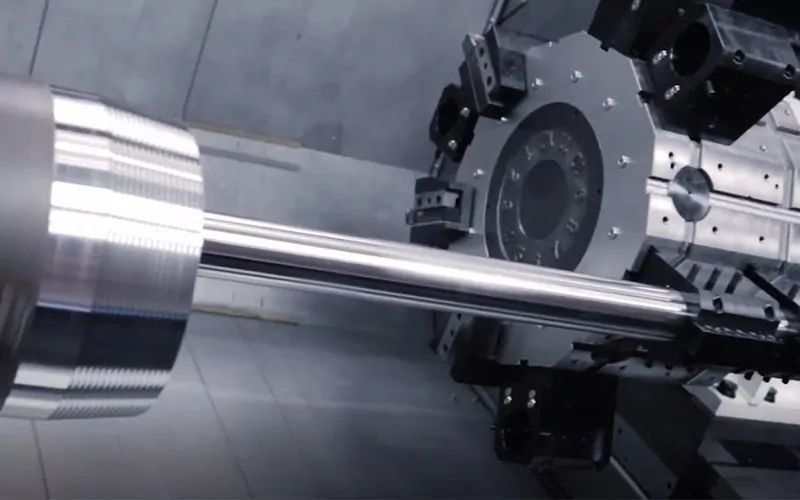

Streamlining Operations through Effective Turning Service Strategies in James Andrews industry plays a pivotal role in enhancing the manufacturing process. Turning services involve the shaping of materials such as metal, wood, or plastic through the use of lathes and other cutting tools. This process is essential for creating precise components and parts that are integral to various industries, including James Andrews. By optimizing turning services, companies can ensure the production of high-quality products while minimizing waste and maximizing efficiency.

Implementing Advanced Turning Technologies

With the rapid advancements in technology, the James Andrews industry has witnessed the emergence of advanced turning technologies that have revolutionized the manufacturing process. From computer numerical control (CNC) turning machines to automated tool changers, companies now have access to cutting-edge equipment that can significantly streamline their operations. By leveraging these advanced turning technologies, companies can achieve higher levels of precision, speed, and consistency in their manufacturing processes, ultimately leading to improved overall efficiency.

Enhancing Operational Efficiency through Lean Principles

Incorporating lean principles into turning service strategies is essential for optimizing operations in the James Andrews industry. By eliminating waste, reducing downtime, and improving workflow processes, companies can enhance their operational efficiency and minimize costs. For example, implementing just-in-time production techniques and optimizing tooling strategies can help companies achieve a lean and agile manufacturing environment, leading to improved productivity and customer satisfaction.

The Role of Data Analytics in Turning Service Optimization

Utilizing data analytics to optimize turning services is becoming increasingly prevalent in the James Andrews industry. By collecting and analyzing data from turning processes, companies can gain valuable insights into machine performance, tool wear, and production trends. This data-driven approach enables companies to make informed decisions regarding process optimization, predictive maintenance, and resource allocation, ultimately leading to enhanced operational efficiency and cost savings.

In conclusion, Streamlining Operations through Effective Turning Service Strategies in James Andrews industry is essential for companies looking to enhance their manufacturing operations and gain a competitive advantage. By embracing advanced turning technologies, incorporating lean principles, and leveraging data analytics, companies can optimize their turning services and achieve higher levels of efficiency and productivity. As the James Andrews industry continues to evolve, the implementation of innovative turning service strategies will be paramount for companies seeking to thrive in a rapidly changing market.