In today's rapidly evolving industrial landscape, the demand for precision and efficiency has never been higher. This is where CNC (Computer Numerical Control) manufacturing comes into play, revolutionizing the way various industries operate and produce goods. From automotive to aerospace, healthcare to electronics, CNC manufacturing has become an indispensable tool for achieving unparalleled accuracy and productivity.

The Role of CNC Manufacturing in Precision Engineering

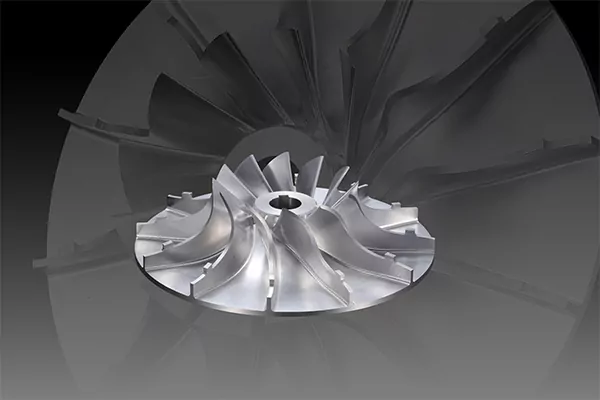

When it comes to precision engineering, CNC manufacturing stands at the forefront. By utilizing advanced software and cutting-edge machinery, CNC processes enable the production of intricate and complex components with microscopic tolerances. This level of precision is crucial in industries such as aerospace, where the slightest deviation can have catastrophic consequences. CNC machining ensures that every part meets the exact specifications, leading to safer and more reliable products.

Enhancing Efficiency through CNC Manufacturing

Besides precision, CNC manufacturing also significantly enhances efficiency across various industries. Traditional manufacturing methods often involve time-consuming manual labor and are prone to human error. In contrast, CNC machines operate with minimal human intervention, allowing for continuous and automated production processes. This not only reduces the risk of errors but also accelerates the overall production timeline. As a result, industries can meet market demands more effectively and stay ahead of the competition.

Application of CNC Manufacturing in the Automotive Industry

One of the most prominent sectors benefiting from CNC manufacturing is the automotive industry. From engine components to intricate interior parts, CNC machining plays a pivotal role in producing high-precision parts that are essential for vehicle performance and safety. The ability to replicate identical parts with utmost accuracy has revolutionized the automotive manufacturing process, leading to improved vehicle quality and reliability.

Medical Advancements through CNC Manufacturing

In the healthcare sector, CNC manufacturing has paved the way for groundbreaking advancements in medical devices and equipment. From surgical instruments to prosthetics, the precision offered by CNC machining ensures that these critical tools meet the stringent requirements of the medical field. Furthermore, the efficiency of CNC processes enables the rapid production of customized medical components, ultimately benefiting patients and healthcare professionals alike.

As we can see, cnc manufacturing has become the cornerstone of precision and efficiency in various industries. Its ability to deliver unparalleled accuracy and streamline production processes has transformed the way products are designed and manufactured. With continuous advancements in technology, CNC manufacturing is poised to further elevate the standards of quality and productivity across the global industrial landscape.